Electronic

Projects Online - Testcard Generator

Originally published

by Paul Stenning

in ETI, December 1991 and January 1992

Tom Payne has developed

a method of replacing the SAA1043 with a SAA1101, and kindly supplied

details. Link is in the list below.

Introduction

There have been several designs of test pattern

generators published in the past, invariably they produce the standard

cross-hatch pattern, possibly horizontal and vertical lines, and may-be

a grey-scale. Most current designs are based around the ZNA234E monochrome

test pattern generator IC.

This

is adequate for monochrome (black and white) equipment, however for servicing

colour televisions and video recorders, something a little more comprehensive

is really required. The instrument featured here provides an impressive

range of patterns including a full colour Test-Card, colour bars, crosshatch,

grey-scale, focus grid, colour purity patterns and more - for considerably

less cost than a commercial unit of lower specification!

This

is adequate for monochrome (black and white) equipment, however for servicing

colour televisions and video recorders, something a little more comprehensive

is really required. The instrument featured here provides an impressive

range of patterns including a full colour Test-Card, colour bars, crosshatch,

grey-scale, focus grid, colour purity patterns and more - for considerably

less cost than a commercial unit of lower specification!

The unit also features a basic sine-wave audio

oscillator, set at 800Hz. The audio and video outputs are available from

the audio and video output sockets and, for more modern equipment, the

SCART socket. An RF modulator is provided for connection to the aerial

socket of UK standard Televisions and Video Recorders (readers in other

countries using the PAL standard may need to obtain a suitable type of

modulator locally). The audio and video signals to the modulator are individually

switchable to either the internally generated signals or to the external

audio and video input and SCART sockets.

A Scope Trigger Output socket is provided to

give reliable triggering on an oscilloscope when trying to view the video

signals, the output from this can be switched to either line or frame

sync.

Features and Specifications

Test Card: Full

colour Test-card featuring colour bars,

grey

scale (0%, 25%, 50%, 75% & 100%),

frequency

bars (0.5, 1.0, 1.25, 1.66, 2.5 & 5.0 MHz),

cross

hatch, low frequency blocks & needle pulse.

Other Patterns: Colour

bars 1 (black to white),

Colour

bars 2 (white to black),

Cross

hatch, Vertical lines,

Horizontal

lines, Dots, Focus grid,

Blank

raster, White raster.

Colour/Mono Switch: Removes chrominance

(colour information) from Video

signal,

thereby converting colour bars to grey scale,

and

removing herringbone patterns.

Red/Green/Blue Completely

remove information for that colour

Switches: from

video signal.

Internal Audio: 800

Hertz (nominal) Sine wave.

Video Out: 1V

Pk-Pk PAL Composite video from pattern generator,

BNC

socket.

Audio Out: 500mV

RMS, 800Hz Sine Wave, Phono socket.

Video In: 1V

Pk-Pk PAL Composite video, Input Impedance 75R or

500K

switchable, BNC Socket.

Audio In: 500mV

RMS into 10K, Phono socket, 30Hz to 15KHz +/-3dB.

SCART Socket: All

signal levels as above.

Pins

1 & 3, Audio out.

Pins

2 & 6, Audio in.

Pin

19, Video out.

Pin

20, Video in.

Pin

8, +12V via 4K7.

Pins

4,14,16,17,18 & 21, Ground.

Other

pins not connected.

RF (UHF) Output: UK

Channel 36 (591.5MHz) with 6MHz Sound Carrier.

Phono

socket.

Scope Trig Output: 5V Pk-Pk

@ 10K, switchable Line or Frame.

Power Input: 220-240V

AC 50Hz @ 6VA or 11 to 13V DC @ 120mA (see text).

How it Works

Most of the difficult work is done by IC9 (TEA2000),

the PAL Colour Encoder IC, and surrounding circuitry. This IC produces

the luminance (brightness) and chrominance (colour) signals and combines

them to form the PAL standard composite video output. The IC requires

6 bit colour data, giving a total of 64 possible colours; it also requires

composite sync and blanking signals which are produced by IC10 (SAA1043),

a Universal Sync Generator IC. Various other signals are obtained from

IC10 for use as clock and timing signals for the remainder of the logic

circuitry. The H1 and V2 signals from this IC go to SW1, which selects

the signal to connect to SK1 (Scope Trig Socket) via R4. The colour data

required by IC9 is stored in EPROMs IC6 & IC7. IC6 contains the data

for the test card whilst IC7 contains the data for the other patterns.

As mentioned previously, IC9 is capable of

producing 64 colours, however for this application only 10 are required.

There are 2 data lines on IC9 for each of the 3 primary colours, labelled

R0 & R1 for red, G0 & G1 for green and B0 & B1 for blue. Taking

the red lines for example, if R0 only is high a fairly dark red (50% of

maximum brightness) is produced, if R1 only is high the colour is brighter

(75% of maximum brightness), if R0 and R1 are both high the colour is

maximum brightness (saturated, the same brightness as white), and if R0

and R1 are both low no red is produced. The same arrangement applies for

the green and blue data lines. By applying various codes to the data lines,

the primary colours can be mixed in various combinations to produce an

impressive range of colours.

The truth table below shows the codes required

for the ten colours used in this application:

Colour R0

R1 G0 G1 B0 B1

---------------------------------------

Black 0

0 0 0 0 0

Blue 0

0 0 0 0 1

Red 0

1 0 0 0 0

Green 0 0

0 1 0 0

Magenta 0 1

0 0 0 1

Cyan 0

0 0 1 0 1

Yellow 0 1

0 1 0 0

Dark Grey 1 0 1

0 1 0

Light Grey 0 1 0

1 0 1

White 1 1

1 1 1 1

From the above truth table it can be seen that

all the colours except black, white and grey are used at the 75% brightness

level, this level is chosen mainly because a good grey-scale is produced

if the colour bar pattern is selected and the chrominance (colour information)

is disabled. The logic levels on lines R0, G0 and B0 are always the same,

these 3 lines therefore share one data line (D0) from the EPROMs, leaving

more data lines available for other purposes. R1, G1 & B1 are connected

to data lines D1, D2 & D3 respectively.

Unfortunately the TEA2000 (IC9) will only produce

2 shades of grey, 50% and 75%, for the test card an additional grey at

25% is required. This is achieved using Q1 and R19 to reduce the luminance

signal level at the luminance delay line. This transistor is controlled

by data line D4, when the 25% grey is required, the 50% grey is selected

and D4 is taken high (a slight problem with this arrangement is that when

the test card pattern is selected, and all 3 colours are switched off,

a faint pattern will still be present, however since the instrument would

never be used in this manner, it was not considered important).

The address lines of the EPROMs, IC6 &

IC7 are controlled by two counter IC's, IC2 & IC3 (note that only

one EPROM, either IC6 or IC7, is selected at any one time, depending on

the position of SW2). The first counter, IC2 (74HC4040), is clocked by

a 5MHz clock signal taken from the crystal (XT1) of IC10 (via IC1:B);

the counter is reset at the end of each scan line by the composite blanking

signal (CB), also from IC10. This counter controls the EPROM address lines

A0 to A7. During the non-blanked period of a scanned line (when CB is

low) there are actually 258 clock pulses, so lines A0 to A7 count up from

0 to 256 (00h to FFh), then to 0 and 1 (00h and 01h) again. The fact that

the first two "pixels" in each line are repeated again at the end of the

line is of no consequence since this has been allowed for when planning

the pattern data.

A second counter chip, IC3 (74HC4024), is normally

clocked on each line by the composite blanking signal (via IC5:A), and

reset at the end of each frame by the V2 (Vertical Pulse 2) signal, also

from IC10. Six output lines from IC3 control the remaining six address

lines on IC6 (we will come to IC7 later), however since there are only

six address lines this gives a maximum count of only 64 lines. Since there

are about 280 visible lines per half frame (remember the 625 lines are

made up over 2 frames), some means of obtaining the 280 lines is required.

The obvious approach would have been to use larger EPROMs (more address

lines), however these could be difficult to obtain and get programmed,

and would make the unit more complex and expensive than planned. The Test-Card

pattern has many sections where one line is repeated several times over,

so the following arrangement was designed, where the same data in the

EPROM could be used for several lines if required. If data line D7 goes

high the rising edge resets another counter, IC4 (74HC4024), via C2 and

R2. Output line Q5 of this IC goes low which switches the CB signal off

of IC3 and on to IC4, via IC5:A and IC1:B. After 16 pulses on the CB line,

line Q5 goes high again, switching the CB signal back onto IC3. Therefore

if D7 is high during a picture line, that line is repeated 16 times. With

careful pattern programming the 64 sets of line data produced the required

full 280 line picture.

The above arrangement is fine for IC6, the

Test-Card EPROM, which only contains one frame, IC7 on the other hand

contains the data for 8 patterns. However these other patterns are made

up of only 8 picture lines repeated several times over to make up the

frame. Therefore only the lower 3 address lines from IC3 need to be connected

to counter IC7, the upper 3 address lines from IC7 are connected to positions

2 to 8 of SW2 (Pattern Select), via diodes D3 to D11, which act as an

8 into 3 line binary decoder, in conjunction with pull-up resistors R6

to R8. Switch position 1 selects IC6 and disables IC7, giving the Test-card

pattern.

The data line outputs of IC6 and IC7 are connected

to an 8 bit D-type latch, IC8 (74HC574). This latch is clocked by the

5MHz clock via IC1:C. The main purpose of this is to remove the effects

of the propagation delays of IC2 and IC6/IC7, which would otherwise give

rise to black vertical lines on the picture, particularly at points where

several address lines are supposed to change state simultaneously. IC8

is also used to produce the 5MHz part of the frequency grating on the

test-card. If line D6 is high the 5MHz clock signal is applied to the

OE (Output Enable) pin of IC8, due to IC5:C & IC5:D. When this clock

signal is high the outputs are disabled and are pulled low by resistors

R11 to R14, when the clock is low the outputs are enabled and high due

to D0 to D3 being high; thereby giving a 5MHz signal on all the colour

data lines. The outputs of IC8 are also disabled (due to IC5:C) when SW2

is in position 9, giving the Blank Raster pattern.

The colour data outputs of IC8 connect to IC9

via switches SW3 to SW5. These switches enable each of the primary colours

to be switched on or off independently.

If switch SW6 (Colour/Mono) is closed, Q2 is

turned on which removes the chrominance from the signal by effectively

shorting out the chrominance filter circuit (L2 & C10) of IC9.

The composite video output from IC9 (COVO),

is attenuated by R39 and R40, and fed to SW8 (the Int/Ext Video switch);

it is also buffered by a video amplifier comprising of Q3, Q4 and surrounding

circuitry, and fed to the Video Output socket (SK3), and pin 19 of the

SCART socket (SK6). The external video input from SK2 or pin 20 of SK6

is amplified by another similar video amplifier circuit, built around

Q5 & Q6. The input impedance of this amplifier is about 500K, but

can be reduced to about 75R by closing SW7. The output of this amplifier

is also fed to SW8. Either the internal or external video, as selected

by SW8, goes to the RF modulator MOD1.

The audio oscillator is built around IC11:B

and is a standard Wein Bridge circuit, with zener diodes used to control

the negative feedback. The output is connected to SW9; and also attenuated

to 500mV RMS (by R53 and R54), and fed to the Int Audio Out socket (SK5),

and pins 1 & 3 of the SCART socket (SK6). The frequency is set to

800Hz, but can be changed to 1KHz if required by reducing R51 and R52

to 16K.

The External Audio input is amplified by IC11:A.

The gain is arranged such that a 500mV input gives the same drive to the

modulator as the internal audio generator. The bandwidth is limited to

30Hz-15KHz by C26 and C27. The output also goes to SW9. IC11 is powered

from the 12 volt supply, with the 5 volt supply used as the mid-rail.

The outputs are about 8 volts peak-to-peak, centred at the 5 volt level.

SW9 selects either the internal or external audio, and R45 & R46 reduce

the level to about 4 volts peak to peak, centred at 2.5 volts, which is

the correct level for the RF modulator, MOD1. C28 removes the small amount

of 6MHz carrier signal that seems to come out of the modulator's audio

input, and would otherwise find its way onto the Audio Output socket.

RV1 is the 6MHz audio carrier fine tuning control.

The power supply uses a standard 12-0-12 volt

centre tapped mains transformer, with full-wave rectification, giving

about 17 volts DC across C11. This is regulated to 12 volts and 5 volts

using two standard 3-pin regulator IC's (IC12 and IC13).

If required T1 could be removed, IC12 linked

out, and the circuit powered from 12 volt (+/- 1 volt) batteries for portable

use. Current consumption at 12 volts is about 120mA, so a small rechargeable

sealed lead-acid battery would be a good choice. The maximum supply voltage

for IC9 is 13.2 volts, so ensure this is never exceeded (disconnect the

battery when recharging).

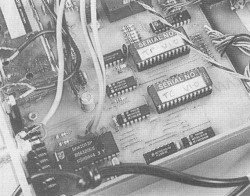

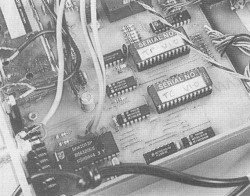

Construction

All the components except the switches, sockets

SK1 to SK5, mains transformer T1 and resistor R4 are mounted on the PCB.

This is a single sided board, about 185 x 165 mm in size, and is available

from the ETI PCB service, order number ****, see page ***. There are 45

links and it is advisable to fit these first, using tinned copper wire,

about 24 SWG. The remaining components can then be fitted in the usual

size order. Note that there are tracks between many of the IC pins so

a fine tipped soldering iron and due care should be used. All the IC's

except IC12 and IC13 (the regulators) should be fitted in sockets, and

should not be inserted until the power supply voltages have been checked

- see Testing and Setting-up. Veropins may be used for the off-board connections

if desired. Take care particularly when fitting the inductors, crystals

and variable capacitor since they are easily damaged by rough handling

and excessive heat. When fitting the modulator, ensure it is well down,

then twist the mounting tags by about 45 degrees and solder. Do not connect

the wires from the modulator to the board until the power supply voltages

have been checked.

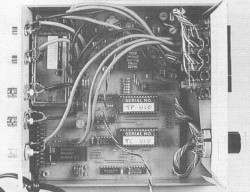

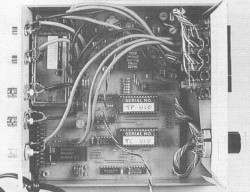

The

prototype was housed in a plastic case approximately 170x70x190mm, however

this was a little tight for comfort. Since the instrument is mains powered,

a slightly larger earthed metal case would be more suitable. The PCB is

mounted at the rear of the case, with cut-outs in the rear panel for the

SCART socket and the UHF output socket on the modulator. The other sockets

are also mounted on the rear panel.

The

prototype was housed in a plastic case approximately 170x70x190mm, however

this was a little tight for comfort. Since the instrument is mains powered,

a slightly larger earthed metal case would be more suitable. The PCB is

mounted at the rear of the case, with cut-outs in the rear panel for the

SCART socket and the UHF output socket on the modulator. The other sockets

are also mounted on the rear panel.

All the switches are mounted on the front panel,

a suitable legend is shown in fig **. Switch SW2 is a rotary type, 1 pole

12 way, with the stop set at position 10 (note that no connection is made

to pin 10, although position 10 is used). The other switches are the Japanese

type latching switches, and are mounted in two banks of four. The individual

switch latches are left in place and the interlocking mechanism is not

used.

The inter-wiring is shown in fig **, thin coax

cable is used for all signal wiring (proper 75R coax could be used for

the video but it is not too important with the lengths involved), and

standard hook-up wire for the remaining connections. The mains connections

should be insulated, and the flex secured in some manner. No mains on/off

switch or fuse were fitted on the prototype, however they could be fitted

if required. The mains plug should be fitted with a 3 amp fuse.

Testing and Setting-Up

Due to the cost of the modulator and some of

the IC's it is a good idea to check that the power supply voltages are

correct before fitting these parts. Make sure none of the IC's except

IC12 and IC13 are fitted, and that the modulator is disconnected. Give

the PCB a final visual check over, in particular watch for solder bridges

between IC pads and the tracks between them.

Connect the instrument to the mains, and switch

on. Set your test meter to 20 volts DC or thereabouts, and connect it's

negative lead to the case of the modulator. Check for 12 volts +/- 0.5

volts on pin 11 of IC9 socket, and 5 volts +/- 0.25 volts on pin 20 of

IC8 socket. If all is well switch off and wait a minute or so for the

power supply capacitors to discharge, then connect up the modulator and

fit the IC's. Most of the IC's are CMOS types but have protected inputs

so static damage is unlikely, however the usual handling precautions against

static discharge should still be taken.

Set SW2 to position 1 (full ACW); SW3, SW4

& SW5 on, SW6 off and SW8 & SW9 to Internal (all buttons out).

Connect the RF output socket on the modulator to your TV, cross your fingers

and switch on. You will probably need to tune your TV to channel 36, although

the channel you use for your video recorder should be somewhere near.

You should get an audio tone from the speaker and a test-card picture.

Don't worry at this stage if there is a buzz on the sound or no colour

in the picture.

To avoid damage to components and misleading

results, always use a proper trim-tool when making adjustments. Adjust

RV1 for minimum buzz (or to the middle of the area of no buzz) on the

sound. Adjust VC1 until the colour locks on, then set to the centre of

the range where you get colour. Finally adjust L2. If you have a 'scope

connect it to the Video Output socket and adjust for maximum amplitude

on the colour burst, otherwise adjust for brightest colour and minimum

"herringbone" pattern on the picture. All that remains now is to check

the various functions of the unit as detailed below. Once the unit has

been tested, the PCB can be fitted in the case, and the unit finished

off.

In Use

Firstly a word of warning. Anybody attempting

to repair or adjust Television Sets, whether using this instrument or

not, must be aware of the hazards involved. Many sections of TV circuitry

operate at dangerous voltages (in the range of 100V to 30KV), and in many

cases the internal chassis and metalwork is also at a dangerous (mains)

voltage. For maximum safety the set should always be powered via a mains

isolating transformer. If a transformer is not used, no test equipment

should be connected to the set, except to external sockets, and very great

care should be taken when making adjustments with the power on (the practice

of disconnecting the mains earth to all the test equipment is extremely

dangerous and should never even be considered). In any event always work

with one hand in your pocket when the set is on, even with an isolating

transformer the high voltages can be lethal. Care should also be taken

when working near the power supply of video recorders, although in this

case the rest of the circuit usually operates at more civilised voltages.

The use of an Earth Leakage Circuit Breaker on the mains feed to the bench

is also a sensible precaution.

In most cases the instrument would be connected

to the equipment under test via its aerial socket, since this enables

the whole signal path to be checked, also a fault in the equipment is

extremely unlikely to damage this instrument when connected this way.

Once the equipment has been proved to be basically sound, the instrument

could be connected by the video/audio or SCART connectors if required.

SW2 selects which basic pattern is produced,

as follows:

Position 1 Test

Card

2 Colour

Bars 1 (Black to White)

3 Colour

Bars 2 (White to Black)

4 Cross

Hatch

5 Vertical

White Lines

6 Horizontal

White Lines

7 White

Dots

8 Focus

Grid (Fine checker board pattern)

9 Blank

Raster (Sync & 0% video)

10 White

Raster (Sync & 100% video)

If SW6 (Colour/Mono) is pressed in, the colour

information will be removed from the picture, this will convert the Colour

Bars to Grey Scale, and remove the "herringbone" patterning on patterns

such as the Cross Hatch.

Pressing SW3/SW4/SW5 will remove the Red/Green/Blue

colour completely, this is the same effect as switching off that colour

gun inside the TV (with all three off there will be no picture). If this

is used in conjunction with the White Raster pattern, the sets colour

purity can be adjusted. It is also useful for removing the blue from the

Cross Hatch when starting to set up the convergence. (If SW3,4 & 5

are all switched off when SW2 is set to the test-card pattern, a faint

pattern will still be present - this should be ignored).

The features of the Test Card require further

comment. The overall size of the picture is slightly smaller than the

minimum size of a transmitted picture. The TV's picture height, width

and position controls should be adjusted such the whole test card is shown,

but with the tips of the corners very slightly hidden by the rounded corners

of the tube (you may find that some cheaper sets have the width adjusted

wider than this, this is because the width of the picture on these sets

varies with brightness). The overall brightness of the Test Card is about

that of an average picture. The background is dark grey (25%) with a white

Cross Hatch pattern, to enable the linearity to be checked.

The

main area of interest on the Test Card is the centre section. Starting

at the top we have a black rectangle within white to check the LF response,

and a white needle pulse to check for reflections and instability. Next

we have a 250KHz, 100% to 0% square wave to test the transient response;

and below this are the eight colour bars. Next there is an six step frequency

grating with frequencies of 0.5, 1.0, 1.25, 1.66, 2.5 and 5.0 MHz. These

enable the frequency response of the video circuits to be checked, the

gratings up to 2.5 MHz should be clear and sharp, but many sets will have

trouble resolving the 5.0 MHz. Finally there is a five step grey scale

for adjusting contrast, with amplitudes of 0%, 25%, 50%, 75% and 100%.

The

main area of interest on the Test Card is the centre section. Starting

at the top we have a black rectangle within white to check the LF response,

and a white needle pulse to check for reflections and instability. Next

we have a 250KHz, 100% to 0% square wave to test the transient response;

and below this are the eight colour bars. Next there is an six step frequency

grating with frequencies of 0.5, 1.0, 1.25, 1.66, 2.5 and 5.0 MHz. These

enable the frequency response of the video circuits to be checked, the

gratings up to 2.5 MHz should be clear and sharp, but many sets will have

trouble resolving the 5.0 MHz. Finally there is a five step grey scale

for adjusting contrast, with amplitudes of 0%, 25%, 50%, 75% and 100%.

I will not go into further details of which

adjustments should be made with which pattern. I you have the service

manual for the equipment this will give suggestions, otherwise it's a

matter of experience and taste - if the set will give an acceptable picture

on all patterns there can't be much wrong! Some sets may have trouble

locking onto the output from this unit, in this case try switching off

the sets AFC and tuning manually. Remember that a test pattern is intended

to show the worst in a piece of equipment. At the end of the day the picture

should be acceptable to the viewer on a normal programme!

As its name suggests, the Scope Trig socket

can be used to externally trigger an oscilloscope when trying to view

the video signals inside the equipment. The output is 5 volts peak-to-peak

at 10K, and can be switched to either line or frame sync by SW1. Bear

in mind, though, that the outer of this socket is earthed inside the unit

so you may be earthing the TV's chassis via the 'scope leads.

When using the video and audio output sockets

it should be noted that the signals from these are always the internally

generated ones, regardless of the positions of the Int/Ext Video and Audio

switches; these switches only affect the output from the RF modulator.

This can be useful if, for example, a video recorder under test is connected

to the SCART socket, and the RF output connected to the workshop TV. The

signal from the generator can be compared to that from the video recorder

merely by operating the Int/Ext switches (no more fumbling with RF leads

behind the TV!). The unit can also be used to enable the composite video

and/or audio outputs from equipment such as video cameras and computers

(and certain satellite decoders!) to be fed to a normal TV via the aerial

socket.

Care should always be taken, particularly when

working on faulty equipment, to ensure that no excessive voltages are

applied to the unit, as this will almost certainly cause expensive damage.

Parts List

Resistors (all 1/4 Watt 5% or better)

R1,2,9,11,12,13,14,16,20,28,34 1K0

R3,4,5,6,7,8,10,23,24,45,46,50,54 10K

R15 3M3

R17,22,55 4K7

R18 36K

R19 620R

R21 910R

R25 10M

R26,33 1M0

R27,35 1K5

R29 6K8

R30,37,38 100R

R31 150R

R32 2M2

R36 3K9

R39 360R

R40 680R

R41 82R

R42,43,47,49,51,52 22K

R44 100K

R48 47K

R53 33K

RV1 2K2

Horizontal Preset

Capacitors

C1,2 1n0

0.2" pitch mylar

C3,4 47p

0.1" pitch ceramic

C5,12,13,15,16,18,20,22,23,29-34 100n 0.2" pitch

disc ceramic

C6 330p

0.1" pitch ceramic

C7,8 5p6

0.1" pitch ceramic

C9,24,25 10n

0.2" pitch mylar/ceramic

C10 82p

0.1" pitch ceramic

C11 1000u

25V radial elect

C14,17,19

220u 16V radial elect

C21,28

220p 0.1" pitch ceramic

C26 220n

0.2" pitch disc ceramic

C27 100p

0.1" pitch ceramic

VC1

22p Trimmer (Maplin WL70M)

Inductors

L1 Delay

Line 270nS (Maplin UH84F)

L2 15uH

Adjustable (Maplin UH86T)

Semiconductors

IC1 74HC02

IC2 74HC4040

IC3,4 74HC4024

IC5 74HC00

IC6,7 27C128-15

150nS EPROM

IC8 74HC574

IC9 TEA2000

IC10 SAA1043

IC11 CA3240

IC12 7812

IC13 78L05

Q1 BC548

Q2,4,6 BC558

Q3,5 BF244

D1,2 2V7

400mW Zener

D3-12 1N4148

D13,14 1N4001

Miscellaneous

MOD1 UM1286

UHF Modulator

SK1,2,3 Panel

BNC Socket

SK4,5 Panel

Phono Socket

SK6 R/A

PCB SCART Socket (Maplin FV89W)

SW1,3-9 DPDT

Latch Push Switch (Maplin FH87X)

SW2 1P/12W

Rotary Switch (Maplin FH42B)

T1

240 to 12-0-12 6VA

XT1 5.000000

MHz (Maplin UL51F)

XT2 8.867238

MHz (Maplin UH85G)

IC sockets (1 x 8 way, 4 x 14 way, 1

x 16 way, 1 x 18 way, 1 x 20 way and 3 x 28 way), Knob for SW2, Buttons

and brackets for SW1 & SW3-9 (Maplin FH61R & FH78K), PCB, Case

170x70x190mm (WxHxD) or larger, Coaxial cable, interconnection wire, tinned

copper wire (about 24 SWG), 3 core 3 Amp mains flex, 13A mains plug with

3A fuse, Phono plug to Co-ax aerial plug lead (Maplin FV90X), other leads

as required, grommet, nuts, screws & spacers.

Buylines

All Components except IC6, IC7 & IC8 could

be obtained from Maplin Electronic Supplies Ltd when the project was originally

written. The Maplin Order Codes for the more obscure components are given

in the parts list. The 74HC574 (IC6) & 27C128 (IC7/8) were listed

by RS/Electromail and several other suppliers.

The data for the EPROMs is provided in Intel-Hex

format - see link above. If you require a different format for your EPROM

programmer, you should download the software for the EPROM Programmer

Mk2 since this contains a utility to convert the data to many popular

formats.

Update (May 1992)

Update notes were published in the May 1992

edition of ETI. Many of these have now been incorporated into the main

text and diagrams, the remaining points are detailed below.

Modification

The wire from colour switch (SW6) to the PCB

should be co-ax to prevent stray pickup affecting chrominance level, a

hole is available on the PCB for the screen. The 0v link between SW6 and

SW3 should be removed and the switch mounting brackets connected to 0v

at SW5.

Buylines

It has come to the author's attention that

150nS 27C128 EPROM's are not too easy to come by. The prototype has since

been tested with 250nS EPROM's which work fine. It should be noted that

the EPROMs must be the CMOS 27C128 types, as normal 27128 devices consume

far too much power and will overload IC13 (the 78L05 regulator) causing

it to current limit.

Maplin have changed their range of 0.1" pitch

ceramic plate capacitors to ceramic disks with a 0.2" pitch, without changing

the order codes! These will fit the PCB if the leads are bent, or the

correct type can be obtained from RS/Electromail.

This

is adequate for monochrome (black and white) equipment, however for servicing

colour televisions and video recorders, something a little more comprehensive

is really required. The instrument featured here provides an impressive

range of patterns including a full colour Test-Card, colour bars, crosshatch,

grey-scale, focus grid, colour purity patterns and more - for considerably

less cost than a commercial unit of lower specification!

This

is adequate for monochrome (black and white) equipment, however for servicing

colour televisions and video recorders, something a little more comprehensive

is really required. The instrument featured here provides an impressive

range of patterns including a full colour Test-Card, colour bars, crosshatch,

grey-scale, focus grid, colour purity patterns and more - for considerably

less cost than a commercial unit of lower specification! The

prototype was housed in a plastic case approximately 170x70x190mm, however

this was a little tight for comfort. Since the instrument is mains powered,

a slightly larger earthed metal case would be more suitable. The PCB is

mounted at the rear of the case, with cut-outs in the rear panel for the

SCART socket and the UHF output socket on the modulator. The other sockets

are also mounted on the rear panel.

The

prototype was housed in a plastic case approximately 170x70x190mm, however

this was a little tight for comfort. Since the instrument is mains powered,

a slightly larger earthed metal case would be more suitable. The PCB is

mounted at the rear of the case, with cut-outs in the rear panel for the

SCART socket and the UHF output socket on the modulator. The other sockets

are also mounted on the rear panel.  The

main area of interest on the Test Card is the centre section. Starting

at the top we have a black rectangle within white to check the LF response,

and a white needle pulse to check for reflections and instability. Next

we have a 250KHz, 100% to 0% square wave to test the transient response;

and below this are the eight colour bars. Next there is an six step frequency

grating with frequencies of 0.5, 1.0, 1.25, 1.66, 2.5 and 5.0 MHz. These

enable the frequency response of the video circuits to be checked, the

gratings up to 2.5 MHz should be clear and sharp, but many sets will have

trouble resolving the 5.0 MHz. Finally there is a five step grey scale

for adjusting contrast, with amplitudes of 0%, 25%, 50%, 75% and 100%.

The

main area of interest on the Test Card is the centre section. Starting

at the top we have a black rectangle within white to check the LF response,

and a white needle pulse to check for reflections and instability. Next

we have a 250KHz, 100% to 0% square wave to test the transient response;

and below this are the eight colour bars. Next there is an six step frequency

grating with frequencies of 0.5, 1.0, 1.25, 1.66, 2.5 and 5.0 MHz. These

enable the frequency response of the video circuits to be checked, the

gratings up to 2.5 MHz should be clear and sharp, but many sets will have

trouble resolving the 5.0 MHz. Finally there is a five step grey scale

for adjusting contrast, with amplitudes of 0%, 25%, 50%, 75% and 100%.